Fast-Track Building And Construction along with Helical Piles: Minimizing Downtime for Services

Commercial websites reside and perish through their schedules. If a retail store has to close, income falls right away. If a data facility drops floor opportunity, the knock-on expenses climb due to the moment. The means our company develop as well as fix structures determines those timetables more than most managers realize. Helical piles sit at the center of the fastest base job I have actually seen on active websites, specifically where accessibility is actually tight, soils vary, and also vibration or digging restrictions are actually genuine. When set up with a very clear program, they compress timelines, avoid moist cement cure windows, and always keep organizations operating while upgrades or repair services continue in the background.

I'll malfunction when helical piles make sense, what a fast-track program in fact resembles, where micropiles as well as resistance heaps port in, and also exactly how to browse the practical truths that calculate whether you finish in times or receive slowed down for weeks.

Why downtime is the statistics that matters

On an office venture, the pure system price of a groundwork system concerns, however the bigger price motorist is opportunity. I have actually observed retail renters conserve 5 bodies by keeping free while teams mounted helical turn in fractional overnight shifts. Industrial clients prevent crane re-mobilization, putting off trades, and also stretched rentals given that helical units allow stalk and also steel to follow right away. In metropolitan areas, a vibration-sensitive laboratory or a bistro with a historical front can easily carry on operating when standard centric heaps or big excavations will have shut them down.

Speed stems from a stack of small performances. Setting in motion a portable gas push scalp as opposed to a big rig, skipping large spoils dealing with, getting rid of formwork and also lengthy treatment times, as well as putting in connection components that is ready to accept lots promptly. That is actually the core conveniences of commercial helical pile installation, as well as it ranges coming from a singular pillar retrofit to numerous overdo a phased redevelopment.

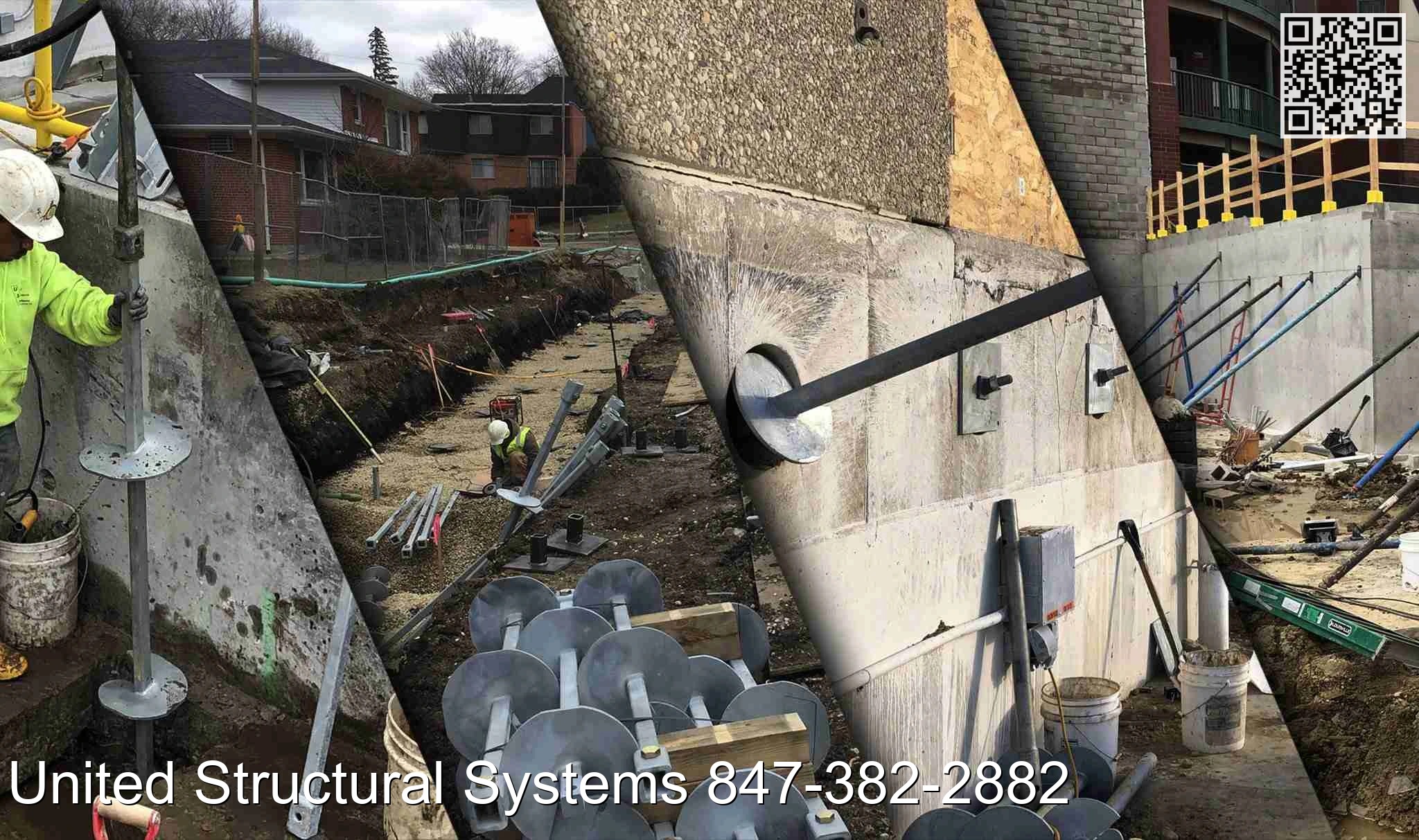

What helical piles in fact are and why they move projects faster

A helical pile is a steel ray along with several helical plates welded along its own length. You tighten it in to the ground along with a twist motor positioned on a skid-steer, little bulldozer, or even bigger bulldozer relying on capacity. The coils breakthrough along with marginal dirt variation, as well as the torque called for to install connects to the axial range. That indicates your field installment information doubles as your proof test, which is actually a massive routine benefit.

The technique is naturally modular. You start with a top area that brings the coils sized and also spaced for the ground account, then incorporate expansions till you hit the concept deepness and also torque. For industrial work, we consistently observe stack operating capabilities in the 20 to 200 kip assortment, at times greater along with larger bars and also multi-helix configurations. Hookup particulars differ: new building and construction braces welded to steel grillage or taken flight to level beams, retrofit brackets for base, or even specialty go to indication properties and also racks.

Because the setup is actually technical rather than cast-in-place, you prevent waiting on concrete to temper. You can execute steel immediately after torque criteria are actually fulfilled and also installation logs are actually authorized off. In high-water-table regions, helical anchors fix uplift without dewatering, and helical tieback anchors maintain excavation walls or even cellar walls without significant interior gain access to. Every one of that makes commercial helical pile installation a go-to when proprietors require building to occur around continuous operations.

Where micropiles and also protection heaps suit the fast-track toolbox

Not every web site yearns for or even allows helical piles. Micropiles and also resistance heaps round out the options, and also each has its place when opportunity is tight.

Micropiles make use of small-diameter taught shafts with high-strength steel as well as concrete grout. They take care of complicated access and also high capabilities in adjustable grounds. In precarious metropolitan cellars where expenses is restricted and also fragments is actually difficult to handle, micropiles shine. They do involve grout, so routine increases arise from quick drilling as well as presented grouting with high-early-strength combines. Micropile installation makes good sense when side demands are small yet central tons are actually higher, or when the ground is actually therefore thick or even debris-laden that helical layers would certainly struggle.

Resistance piles, often called push piers, are actually hydraulically steered steel pipe portions mounted against a construct's weight. For commercial foundation stabilization in an underpinning context, they call for very little digging at the footing and also deliver instant bunch move to deeper bearing strata. When the structure provides adequate response, commercial resistance pile installation may beat the time clock on settlement deal interruptions as well as piece realignments without distressing functions above.

The right phone call often stabilizes soil profile, structural needs, accessibility, as well as permitted resonance. A restaurant on gentle clay-based along with restricted whole lot accessibility often favors helical piles. A retrofit under a massive tilt-up with reduced indoor approval may favor resistance piles. A laboratory with thick sands, dispersed stuffing, and also higher seismic demands may favor micropiles for both axial and sidewise performance when paired with a cap.

Helical tiebacks as well as anchors, the silent heroes of fast shoring

The exact same set up logic administers flat. Helical anchors and helical tieback anchors are actually just helical piles oriented to stand up to sidewise planet pressures. They are actually ideal for temporary or even permanent shoring when you can certainly not tremble the ground or embed soldier heaps. I have put in tieback anchors through existing cellar walls using compact gears, then tensioned them to make lots the very same time. For retail or healthcare locations, that rate stays away from phased fasteners of interior areas. Commercial helical tieback anchor installation is actually especially effective on sites along with electrical congestion, where exact installment angles and also durations steer clear of clashes without large excavations.

Tieback anchors additionally assist throughout deep foundation repair courses. If a structure wall structure is stooping or sliding, you can easily support it without tearing out indoor finishes. That is actually a primary succeed for occupied buildings as well as an usual approach in structural foundation repair where wall surface motion accompanies settlement.

A typical fast-track pattern on an online site

Every task steers its very own pattern, yet a trend surfaces when the target is very little downtime.

- Preconstruction investigation and modeling

- Staged use as well as laydown planning

- Install through zones during off-hours

- Immediate verification as well as bunch transfer

- Follow-on professions without gap days

Preconstruction starts along with a centered subsurface examination. You do certainly not require a number of borings for a little retrofit, however you do need at least sufficient data to prepare coil arrangements as well as forecast depth. I choose a mix of borings and also DCP or CPT soundings if the web site allows. In more mature urban locations, utility mapping is as essential as grounds. You can certainly not pay for a line strike when the store needs to open up in the morning.

With the information in palm, you model the heap team tons, choose shaft diameter and coil configurations, and also established torque criteria based on published connections and any kind of local gradation. If it is a vital facility, intend a pre-production lots test. Yes, it takes a time, however it acquires self-confidence and also commonly velocities approvals.

Staged use keeps operations operating. On a grocery store retrofit, our laydown was an edge of the car park near the packing dock. Our company secured it, established oil control for the hydraulic hose pipes, and also introduced a miniature excavator along with a 10,000 ft-lb travel head. The retail store kept open. Our company arranged work from 10 p.m. to 6 a.m., at that point cleansed as well as demobilized the aisles through opening up time.

Install through regions implies our experts reduced small parts of slab or even excavate outdoor pits, mount the helical piles to torque, and limit them with brackets or even heap limits as soon as possible. The ground spoils are actually marginal and quick and easy to haul in little batches. Noise is low, typically less than a center exercise in concrete as well as orders of immensity below an influence hammer. Resonance is actually imperceptible, which matters if merchandise or even sensitive tools is nearby.

Immediate proof relies upon adjusted twist readings as well as, if specified, proof exams on chosen heaps. When confirmation is actually complete, our company set steel and also transfer lots. On brand new steel mezzanines, I have seen pillars plumbed and also scampered within the very same shift.

Follow-on professions avoid dead time. The system just operates if electrical contractors, steel fabricators, as well as concrete staffs are actually connected right into the exact same routine. You perform not want a best fast-track mount delayed by a missing bottom plate or even an overdue anchor bolt template.

The cost-speed equation that managers ought to understand

Fast-track base job performs not automatically mean cheapest every pile. It normally indicates lowest total expense of ownership for the task home window. I have found helical piles operate 10 to 20 per-cent higher every lot of capability than a slower drilled boat dock option when you simply tally pile products. However when you add the cost savings coming from much shorter general health conditions, fewer shed business days, and lowered short-lived works, the helical solution emerges ahead.

For example, a 12-pile retrofit to assist brand new rooftop units on an energetic medical office building included 2 possibilities. Option A was actually over-drilled chests needing a weekend shutdown, crane picks, and pair of full weeks of phased deal with huge spoil removal. Choice B was actually helical piles mounted coming from the rooftop with a sleek rig and brief beam spreaders, run in night changes. The helical products were actually greater, but the total job ended up a full week previously along with no patient-facing recovery time. The owner's driver calculated cost savings in the tens of manies thousand Commercial Helical Pile Installation coming from uninterrupted clinic timetables alone.

If the internet site is clogged or the dirt profile page is aggressive to helices, that math improvements. Heavy glacial till along with cobbles may chew up coils and delay improvement. In those situations, a hybrid technique with micropiles in the most awful zones and also helical piles elsewhere can still preserve the routine conveniences without forcing the incorrect device into the inappropriate ground.

Foundation fixing on energetic facilities

Commercial foundation repair service needs to have the very same rate lense, especially with occupants in location. Negotiation, wall surface turning, or even slab heave hardly wait on an excellent window. In a lot of retrofit plans, the mix resembles this: helical piles or resistance piles for base, helical tiebacks to arrest side action, as well as targeted piece stabilization with grout or polyurethane injection.

Underpinning with helical piles excels where you can easily subject the ground simply put segments. Teams install stacks at spacing aligned with the architectural bunches, fasten braces, and lift or secure off in position. The structure maintains operating. Commercial foundation repair of this particular type can move linearly down an exterior, pair of or even 3 gulfs every night, regrading sidewalks as you go.

Resistance heaps slip in when the construct delivers enough mass for hoisting, which removes the demand for a big external reaction. That aids in slender indoor hallways or near residential or commercial property lines. For deep foundation repair in clay, our company typically integrate the deriving along with drain improvements, considering that water management is actually half the settlement deal battle.

Foundation fracture repair service becomes part of the package yet certainly not the entire story. If the fracture is an indicator of differential motion, sewing or even epoxy shot alone will certainly dissatisfy. Structural foundation repair indicates maintaining help along with heaps or even anchors, after that dealing with gaps. In much older warehouses, our experts in some cases use tieback anchors to prepare inclined wall surfaces, at that point come back to fill and also sew splits after lots are secure.

Load verification without dropping time

Engineers and building representatives wish verification the heaps will certainly hold what the sketches mention. Helical piles offer a built-in relationship in between installment twist and capacity, yet that is certainly not a permit to miss testing. A brilliant planning guards the schedule.

Use a pre-production compression or strain test on a couple of sacrificial stacks. It confirms the torque-to-capacity think about your ground and sets recognition standards. In the course of manufacturing, depend on continuous twist logs coming from a calibrated scale or electronic system. If the venture is sizable or even essential, include verification examinations on 5 to 10 per-cent of heaps. With helical tiebacks, lock-off lots and also elongation sizes inform you if the support is settling accurately. Each of this may take place during the course of the same shifts as setup, with exam setups that relocate quickly and carry out certainly not obstruct operations.

Micropiles follow a comparable reasoning, although bunch screening commonly includes longer setup. Make use of beam-and-reaction frameworks sized for the on call space. High-early grout assists compress timetables, but always appreciation minimum treatment opportunities tied to grout durability, certainly not just the clock.

Safety as well as access, the quiet components of speed

I have possessed fast-track tasks slow down given that a person underestimated exactly how promptly materials might relocate from laydown to point of work. Slim passages, a singular working elevator, or even an occupied stairwell can easily switch an easy program into a coordinations puzzle. When opportunity is the chauffeur, spend early in get access to preparation: path defense, short-term ramps, evening concierge help, and very clear web traffic balance along with the establishment. Helical pile areas can be found in workable durations, usually 5 to 7 feet, which aids. Micropile housing and also reinforcement could be much heavier and also longer, so planning lifts accordingly.

Noise and also resonance limits matter as well. Helical installation produces a stable gas hum as well as the occasional squeal as the plates cut through particular levels, but the general audio degree normally stays below regular building and construction noise limits. That is why helical anchors and also tieback anchors discover homes in medical facilities and labs. Protection heaps perform produce brief ruptureds of hydraulic jacking sound, yet once more, it is actually usually appropriate after hours.

The other protection part is overhanging. Mini bulldozers and travel heads call for allowance. In tight interiors, we in some cases change to portable or mast-mounted travel devices to keep open spaces. That swap keeps the consider schedule where a full equipment will consistently reposition.

When helical piles are not the fastest answer

Some grounds dismiss. Dense gravelly tills with frequent cobbles, building and construction debris areas, or even shallow bedrock may slow helices as well as burn hours while you make an effort to reduce a pathway. Under those ailments, a micropile along with a drill-through capability, down-the-hole hammer, or even studying development body may be a lot faster in spite of entailing cement. Also, if deterioration disorders ask for massive protection and also the demanded life-cycle finishes, the fabrication lead time for certain helical systems can easily exceed the routine. Alternatives, consisting of galvanized protection heaps or coated micropiles, may be actually a lot more available.

The other restraint is actually lateral performance. Helical piles are great in axial load, yet if the structure demands sizable lateral stiffness without a level beam or pile limit that can share tons, you could reach for larger-diameter punched shafts or even a micropile team created for side action. You can still maintain downtime reduced with organized job, but the stack kind changes.

Coordinating along with establishment as well as utilities

Fast installation loses its worth if the pile scalps do not meet the steel or even if an unexplored conduit traverses your pathway. Early control stays away from the majority of that. On brand-new steel, bolt trends and also base platter fullness should be locked before manufacture. On support, bracket options and elevations require to reflect true ground geometry, certainly not expectations. I like to subject the 1st handful of underpinning bays days just before the primary work, verify sizes, and also readjust brackets or even shims while purchase home windows still enable changes.

Utilities are actually a continuous danger. Personal locates, ground-penetrating radar, and also preliminary fractures are certainly not luxuries on active websites. Due to the fact that helical piles create very little spoils, you can easily pothole, put in, backfill, and also recover in tight areas without leaving behind troughs open. Tieback anchors need to have even more care. Their velocities may converge unfamiliar pipes if the preconstruction survey is actually slim. Specify the support slants and lengths along with an energy chart you rely on, then readjust in the field to avoid conflicts.

Real-world examples that present the tempo

A distribution center required new wrenching rows ranked for higher point loads. Turning off the church aisle was permitted for merely eight hours per switch. Our experts put up helical piles at column factors overnight, four heaps per center, at that point set plates and also discharged the alley through early morning. Over three nights, the full gulf was actually assisted, with no disturbance to daytime operations. The alternative, boring as well as grouting, would certainly have compelled a complete weekend break shutdown and also a week of remedy time.

At a lakefront restaurant along with a settling deck, protection heaps were the victor considering that the existing design provided an ideal response. Our experts cut little accessibility holes with the deck, steered segments until refusal on the deep bearing level, at that point elevated the deck back right into plane. The home kitchen never closed, and the front-of-house seats resumed the next day, a traditional example of commercial foundation stabilization implemented inside tight operating windows.

In a laboratory retrofit, outdoor excavation for a brand-new areaway wall structure required supporting. Helical tieback anchors used coming from inside the cellar, steering clear of any disorder to landscape design or neighboring residents. The supports were tensioned and latched off in a singular switch, letting the digging arise as well as cement observe instantly from shoring evaluations, hammers, or heavy rigs.

Quality management without bureaucracy

Speed performs not pardon sloppiness. The right balance is actually moderate paperwork, massive field verification. Daily logs should grab setup torque, deepness, pile ID, as well as any blockages. Workers photo heads and braces before cover-up. For micropiles, cement set tickets and also dice breathers or cylinder tests verify strengths. For helical anchors, lock-off loads and also creep examinations go in the record. The point is certainly not to create a binder for its very own benefit, but to make certain the group can easily go ahead without backtracking.

Couple that with crystal clear recognition criteria. If torque is short, you prolong or even alter helix setup. If a resistance pile delays early, you reassess strata or even look at predrilling. If a micropile rejects because of clutter, you shift tooling or instance. Decisions created in moments, not times, maintain the program tight.

How owners and also GCs can specify the partner for success

- Decide early whether velocity or even device cost regulations the time, and interact that concern so the structure kind aligns with job goals.

- Give the installer accessibility to actual architectural tons and also particulars, certainly not general varieties. Precise bunches avoid last-second redesigns that eliminate momentum.

- Lock down a sensible job home window along with the establishment crew. Evening work, predisposed fasteners, or rolling barriers all function when everybody knows what is coming.

- Approve an efficient testing protocol just before use. Waiting on choices after the very first pile uses refuses the advantage helical units bring.

- Stage follow-on business to overlap smartly. Building steel, MEP penetrations, and slab patches need to be queued, not arranging an ideal handoff.

The profits on downtime

Speed in foundation work is actually hardly ever the item of one magic device. It stems from deciding on procedures that get rid of nonproductive time, and after that developing a program that appreciates the realities of an occupied web site. Helical piles, helical anchors, and also helical tieback anchors excel due to the fact that they set up promptly, validate simply, and disrupt little bit of. Micropiles and also resistance piles fill the gaps where dirts or properties ask for a different strategy without giving up rate. When blended along with regimented preconstruction as well as on-the-fly area judgment, these resources transform groundwork work from a cessation occasion in to a controlled background process.

For managers, the measurement to keep track of is actually business connection. If the establishment opens up punctually, if the laboratory always keeps running, if the timetable stores without cascading delays, after that the base tactic performed its task. In my expertise, helical piles and their close relatives give you the very best shot at that outcome, as well as they perform it by shaving hours and also days at every measure: less excavation, no remedy waiting, quick lots move, low spoils, light-toned tools, verifiable efficiency. Place those with each other and the course to fast-track building acquires a lot smoother.

UNITED STRUCTURAL SYSTEMS OF ILLINOIS, INC

2124 Stonington Ave Hoffman Estates, IL 60169 847-382-2882 [email protected]> Mon-Fri 8:30am-5:00pm Sat-Sun By Appointment