Step-by-Step Compliance: New Security Codes for Residential Air Conditioning Installations

Keeping up with residential HVAC code updates feels less like reading a rulebook and more like tracking moving targets. The last few code cycles have layered in cybersecurity concepts, refrigerant transition rules, and electrical protection standards that hit installers where they live: on site, with a drill in one hand and a phone buzzing with change orders. This guide distills the practical pieces of the new security-focused requirements and shows how to fold them into a clean, defensible workflow for Air Conditioning Replacement or new installs. If you manage Air Conditioning technicians or run the truck yourself, the aim is the same: deliver a system that performs, pass inspection the first time, and avoid callbacks that drain margins.

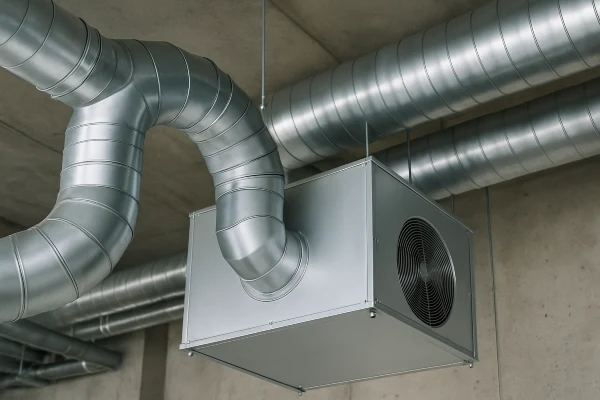

Why “security” belongs in the mechanical room

Security used to mean locking the condensing unit cage and not leaving copper in plain view. Now the term stretches to networked controls, tamper-resistant installations, and preventing refrigerant release or theft. The shift has three drivers: connected thermostats and communicating equipment, updated anti-theft and safety ordinances, and refrigerant transition risks as homes adopt mildly flammable A2L blends. When a unit can be controlled over Wi‑Fi and a single wiring error can disable a whole variable-speed system, security moves from afterthought to a core design constraint.

Municipal amendments vary, but several themes recur. Inspectors want proof that connected components are configured with secure defaults, that refrigerant systems include appropriate leak mitigation and labeling, and that outdoor equipment can’t be easily compromised. If you work in multiple jurisdictions, treat security as a standard practice with local twists, not as an à la carte add-on.

The code landscape in plain terms

Codes that touch security for residential air conditioning installations normally arrive through three channels. Electrical codes add requirements about disconnects, surge protection, GFCI or AFCI coverage, and bonding. Mechanical codes and refrigerant standards set placement, ventilation, and equipment labeling for A2L refrigerants. Building and property maintenance codes add anti-theft, screening, and access control. Overlay that with manufacturer instructions, which are not suggestions. In most jurisdictions those instructions carry the force of code, and they often contain explicit cybersecurity language for connected components.

Expect cross references between your electrical and mechanical inspection tags, and expect the inspector to ask for documentation: model numbers, wiring diagrams, torque specs, setpoints, and in some cases screenshots of network settings. The fastest path through inspection is to prepare that packet before you pull the vacuum pump.

Job planning that preempts security red flags

Permit applications rarely request a security narrative, but plan as if they do. I carry a one-page worksheet in the van that flags three topics during the site walk: outdoor unit exposure, refrigerant classification for the selected equipment, and network/control topology. Those checks shape how I write the proposal and how I stage Residential Air Conditioning tools for the actual day of install.

Outdoor exposure sounds like common sense, yet I still see brand-new condensers installed under a bedroom window within easy reach. That raises theft risk, noise complaints, and sometimes violates clearance rules. Shifting the pad by a few feet to maintain sight lines from the street and access from the service side gives you leverage with both inspectors and homeowners. It also allows simple security add-ons like tamper-resistant fasteners without turning the yard into a fortress.

Refrigerant classification holds more hidden complexity. With A2L refrigerants, the room volume, mechanical ventilation paths, and ignition source clearance become checklist items. You do not want to discover at startup that a simple closet return grille puts you outside the labeling or that the furnace control board does not meet the required separation. Pair the equipment selection with the room geometry early.

Controls and networks cause the most confusion on the https://padlet.com/edisaacelnegroxajpv/bookmarks-n46xnm8vxgwffbuj/wish/zV61Q6Xdg3ERWO98 day of commissioning. A standard split with a basic two-stage thermostat still demands secure installer setup. Communicating systems add a fourth layer: the homeowner’s Wi‑Fi and the cloud services behind it. If you set expectations and collect the necessary router access details ahead of time, you can configure secure defaults without guessing passwords in a hot attic.

A practical sequence that aligns with the new rules

Technicians thrive on clear order of operations. Security requirements slot into the familiar flow without reinventing it. Think of them as guardrails at key stages rather than extra errands at the end.

Pre-install documentation and inventory

I keep a thin folder for every job: spec sheets, wiring diagrams, torque charts, electrical one-line, and any city or utility program notes. If the equipment supports networked control, add the manufacturer’s security checklist or commissioning guide. Do not rely on memory for torque and flare specs, especially with new refrigerant blends and updated service valve designs.

For field inventory, check that your Residential Air Conditioning tools match the system class. A2L-compatible gauges and recovery machines, spark-free leak detection where required, and rated shrouds for brazing in tight spaces. Surge protective devices compatible with the outdoor unit’s MCA and MOCP. Tamper-resistant hardware for line set covers and electrical whip terminations. Label stock that can survive UV and the homeowner’s sprinklers.

Site prep, clearances, and anti-tamper

Pad placement sets the tone. Aim for good drainage, code clearances on all sides, and sight lines that deter casual theft. I like to set the pad with a slight forward slope so runoff goes away from the structure and not into electrical. If the property has had theft issues, spec a cage that allows airflow and service access without inviting galvanic corrosion. Many municipalities forbid cages that impede disconnect access, so choose a hinged design with a keyed latch.

Line set routing becomes a security detail as well as an aesthetic one. Use continuous covers where possible and cap them with tamper-resistant screws. If the route passes along a fence, keep the cover standoff far enough that a reciprocating saw cannot find the copper on a straight cut. It’s not paranoia to run the suction line closer to the wall and the liquid line on the outside, so a clean cut gets the less valuable tubing first.

Electrical protection and proper disconnects

Several jurisdictions now treat outdoor units as sensitive electronic equipment that require surge protection. If the main service already carries a whole-house SPD, confirm its rating and note it in your packet. Otherwise, mount an appropriately sized SPD at the disconnect or panel feeding the condenser. Land it with short, straight leads and torque to spec. A two-inch loop looks tidy, but it kills SPD performance.

Grounding and bonding deserve extra scrutiny. Installers sometimes rely on EMT continuity and overlook a proper bonding bushing or strap. The new equipment you install likely has delicate control boards. Solid bonding reduces nuisance trips and protects electronics, which aligns with the intent behind security codes.

GFCI or AFCI requirements for outdoor receptacles and circuits vary, and 240-volt GFCI protection on condenser circuits remains a local call. If your area enforces it, test-trip the device and log the result with your commissioning notes. If not enforced, consider providing it when nuisance trips are unlikely, especially on inverter-driven equipment that tolerates it. This becomes a selling point and a risk reducer.

Refrigerant management with A2L considerations

If you’re working with A2L refrigerants, treat leak prevention and ignition source control as part of security compliance. Choose brazing locations with adequate ventilation. If joints must be made near a furnace or water heater, temporarily disable ignition sources. Post the appropriate hazard label at the equipment and, when required, along the line set path. Apply the manufacturer’s maximum charge calculations honestly for the room volume. Inspectors increasingly ask for those numbers on paper.

I’ve seen techs rush flares on mini-splits to save time and pay for it with callbacks. With A2Ls, a tiny leak triggers homeowner anxiety and sometimes inspector rechecks. Use a calibrated torque wrench for flare nuts, a consistent drop of lubricant, and cap everything during transport. Pull a deep vacuum, isolate, and wait. If your vacuum rises more than a handful of microns over five minutes, find the leak before you charge. It’s not only a performance issue, it’s a safety one tied into the new code expectations.

Control wiring and secure setup

Security on the low-voltage side starts with routing. Keep thermostat cables away from high-voltage conductors. Label both ends. Land conductors with ferrules where spade terminals invite slippage. For communicating systems, follow the manufacturer’s twisted-pair or shielded cable guidance. I keep a small stock of shielded 18/4 because it eliminates half the noise issues that masquerade as board failures.

When you reach the thermostat or the controller hub, resist the urge to accept default credentials. Set a unique installer PIN. If the system exposes a local web interface, change the default password and disable unnecessary services such as open onboarding modes once you complete pairing. Several manufacturers now include a security tab in their commissioning app. Use it. Take timestamped screenshots of the final settings and file them with the job documents. Some inspectors will not ask, but having proof that you changed defaults shields you when a curious teenager reads a QR code and starts toggling the fan from a PlayStation.

For Wi‑Fi thermostats, encourage homeowners to create a dedicated IoT network on their router, or at least a separate SSID with a strong passphrase. Keep the app accounts in the homeowner’s name, not yours. The moment an installer holds secret keys to a home device, you inherit liability that extends far beyond comfort calls.

Physical security and tamper evidence

Simple details matter. Use lockable service caps on refrigerant ports to deter huffing and casual tampering. Many code packages either require them or cite them as best practice. Weatherproof the disconnect and secure the whip so it cannot be yanked loose without tools. If you install a cage, leave a spare key in a sealed envelope with the permit packet and log who receives it. Document serial numbers of outdoor units; that speeds police reports and insurance claims in the rare event of theft.

The outdoor nameplate and labeling should stay readable for years. UV-resistant labels for circuit identification and A2L warnings save the homeowner and the next technician from guesswork. I also leave a laminated quick sheet near the air handler or furnace with model numbers, filter sizes, breaker identifiers, and the installer PIN sealed in a separate tamper label that the homeowner can open if they lose their notes. That sheet resolves a surprising number of service calls without a truck roll.

Commissioning with a security lens

Commissioning tends to focus on airflow, charge, and control response. That does not change. Layer three security checks right before you wrap the job: updated firmware, verified protective devices, and network hygiene.

Firmware updates should be applied from a trusted app or the manufacturer’s site, not from a random QR code in a forum. Document the version numbers. If an update changes default behaviors, retest all safety interlocks, especially float switches and high-pressure cutouts.

Protective devices include the SPD, any GFCI devices in the circuit, and lockable caps. Test the SPD indicators and the GFCI trip. If you can, simulate a condensate blockage to confirm the float switch kills the outdoor unit as intended. Float switches are not security devices by name, but they protect property and reduce insurance headaches that tend to invite stricter local rules.

Network hygiene is less visible but just as important. Confirm the thermostat or hub is on the intended SSID, has a strong passphrase, and does not broadcast open onboarding after commissioning. If the controller offers usage analytics or remote diagnostics, review the privacy settings with the homeowner and disable what they do not need.

Training crews without slowing them down

Shoving new security steps onto a busy crew can backfire. Time them instead. On most installs, the added steps amount to minutes, not hours, when planned well. Changing an installer PIN, tearing a lockable cap, tightening tamper screws, and snapping a few screenshots add about ten minutes. Labeling can be done while the vacuum pump runs. Surge protector install fits the same window while the line set cools after brazing.

Where teams hit delays is with networking. A missing Wi‑Fi password can stall a crew. Solve it with a pre-job call and a simple script: confirm SSID, password, router location, and permission to reboot if needed. Offer a small discount if the homeowner sets up a separate IoT network in advance, and many will do it.

I hold brief tailgate talks on two topics that cause most callbacks: routing low-voltage away from high-voltage in the attic, and torqueing flares on mini-split branches. When crews own those habits, security compliance follows naturally because the same discipline applies everywhere else.

Documentation that withstands scrutiny

Inspections vary from curbside glances to thorough walk-throughs with checklists. The right paperwork flattens both. I bring a single packet in a clear sleeve. The first page lists the model numbers, serials, permit number, and who performed each step: electrical, refrigerant, controls. The second page holds photos: disconnect wiring, bonding, label placement, and a wide shot of clearances around the outdoor unit. The third page prints the network security changes and firmware versions. In areas with A2L requirements, the fourth page shows the charge calculation inputs and outputs.

That sounds like overkill. It shortens inspections and builds trust. It also protects you if a neighbor calls the city about a perceived hazard because they saw a lockable cap and assumed danger. You can show that you followed current Air Conditioning security codes and manufacturer guidance.

Edge cases you should anticipate

Older homes introduce tricky interactions between new security expectations and legacy infrastructure. Two common ones: shared neutrals on multiwire branch circuits and brittle cloth-sheathed low-voltage cable. Modern equipment hates both. Shared neutrals become a point of failure and a code violation when you add AFCI or GFCI. Cloth-sheathed cable crumbles under staples and fails continuity across longer runs. Budget an extra hour for rewiring in pre-1960s homes, and be ready to explain why you did not reuse the existing thermostat run.

Name: Leander Air Conditioning Repair

Address: 1904 S Bagdad Rd, Leander, TX 78641

Phone: (737) 379-1515

This is the logo of Leander Air Conditioning Repair https://leanderairconditioningrepair.com/assets/leander-air-conditioning-repair-air-conditioner-repair-near-me-leander-tx-logo.png

Leander Air Conditioning Repair is a local Air Conditioning Business located in Leander, TX, 78641

Leander Air Conditioning Repair serves consumers with residential air conditioning emergencies

Leander Air Conditioning Repair offers free quotes and assessment

Leander Air Conditioning Repair address is 1904 S Bagdad Rd, Leander, TX 78641

Leander Air Conditioning Repair phone number is (737) 379-1515

Leander Air Conditioning Repair has the following website https://leanderairconditioningrepair.com

Leander Air Conditioning Repair has the following google map listing https://maps.app.goo.gl/Gxqsa14z8oFiu5SHA

Leander Air Conditioning Repair has this Facebook page https://www.facebook.com/profile.php?id=61580147141792

Leander Air Conditioning Repair has this twitter profile https://x.com/LeanderAirCRep

Leander Air Conditioning Repair has the following Linkedin page https://www.linkedin.com/in/leander-air-conditioning-repair-a09a63382

Leander Air Conditioning Repair has this Youtube channel https://www.youtube.com/@LeanderAirConditioningRepair

Leander Air Conditioning Repair serves residents near Bagdad Cemetery.

Leander Air Conditioning Repair provides services near Leanderthal Lady Marker and Leander High School.

Leander Air Conditioning Repair helps residents close to Leander Police Department.

Attics and tight closets create another edge case with A2L refrigerants. If the room volume barely meets charge thresholds, any later remodel can make the installation noncompliant. Note this in your invoice and suggest a simple mitigation like a louvered door or a grille that maintains volume. Inspectors appreciate the foresight, and homeowners avoid getting caught by surprise after a bathroom remodel.

Vacation rentals pose one more twist. Multiple guests will try every feature of a smart thermostat. Lock core settings behind the installer PIN and clarify setpoint limits. If the homeowner wants remote access for guests, recommend a separate user role where available. That reduces frantic calls when guests accidentally put the system into away mode.

What managers should measure

If you run a team of Air Conditioning technicians, turn security compliance into a scorecard that lives next to first-time pass rates and callbacks. Track three items for each job: installed SPD yes/no, lockable caps yes/no, and network defaults changed yes/no. Review misses weekly. The numbers nudge habits faster than memos. Combine that with spot checks on documentation quality and you get a steady climb toward consistent, low-drama installs.

Vendors and distributors can help. Ask your supplier to bundle tamper-resistant fasteners, caps, and label kits with new condensers. Get training credits for crew leads on A2L installation standards and connected controls security. The distributor’s technical desk usually has the latest manufacturer bulletins about firmware risks or wiring quirks. Keep those in a shared folder with your crew.

Talking to homeowners without scaring them

Security topics can unsettle homeowners if handled bluntly. Keep the language practical. I usually say: we’re taking a few steps to protect your new system from power surges, theft, and accidental changes over Wi‑Fi. Then I point to the SPD at the disconnect, the lockable caps, and the thermostat’s installer PIN. For A2L systems, I explain that the refrigerant is efficient and mildly flammable in concentrated conditions, which is why we installed labels and followed specific ventilation and clearance rules. The tone matters. You are making the system safer and more reliable, not installing a hazardous device.

If customers ask for extras, offer motion lighting or a camera with a clear view of the outdoor unit rather than an overbuilt cage. For network security, suggest a router upgrade if their equipment is dated. The cost of a decent router is less than a single service call spent wrestling with flaky onboarding.

Tools that make compliance feel routine

The best Residential Air Conditioning tools for security compliance are not exotic. A torque wrench for flares and lugs solves half your headaches. A good label maker with UV-rated tape ensures your work stays legible. A compact SPD that fits your preferred disconnect reduces installation friction. A set of tamper-resistant bits saves trips to the van.

On the digital side, keep a secure photo app or cloud folder per job, and store those commissioning screenshots and serial numbers. Use a password manager for installer PINs on demo boards, but never for homeowner accounts. If your company uses field software, build templates that prompt techs to check security items at the right stage. When you open the commissioning screen, the app should ask whether you changed default credentials. Small nudges make big differences across dozens of installs.

When a replacement becomes an upgrade

Air Conditioning Replacement often reveals infrastructure gaps. The old condenser sat on a sinking pad, lacked surge protection, and the disconnect looked tired. The new unit likely includes communicating capability even if the homeowner opts for a conventional thermostat now. Install the backbone for future security: a modern disconnect with space for an SPD, a clean whip, labeled conductors, and a line set cover that can be reopened without shredding. If the budget allows, swap in a thermostat that supports secure onboarding and local control, even if the homeowner declines Wi‑Fi today. A small step now prevents a messy retrofit later.

Replacing the air handler or furnace together with the condenser makes A2L compliance easier because you can rework the cabinet space, add ventilation grilles, and reroute wiring cleanly. If you replace only the outdoor unit, be explicit about what stays the same, what improves, and what must be revisited later to meet evolving Air Conditioning security codes.

A compact field checklist you can adapt

Use this as a pocket guide on install day. Keep it short to avoid list fatigue.

- Verify pad placement, clearances, and line set cover with tamper-resistant screws. Photograph before and after.

- Install disconnect, bond properly, and add surge protection with short leads. Label breakers and equipment.

- Confirm A2L requirements: charge limits, ventilation, hazard labels, and ignition source separation.

- Set unique installer PINs, change default credentials, and disable open onboarding. Document firmware versions.

- Fit lockable service caps, test GFCI/AFCI where required, and log results in the commissioning packet.

What changes next and how to stay ahead

Codes will keep folding in cybersecurity language as more equipment rides on home networks. Refrigerants will keep shifting as manufacturers refine blends and components. Electrical protections will likely grow stricter wherever storms, wildfires, or grid instability drive insurance claims. Staying ahead does not require a library of statutes. It requires a habit of reading manufacturer bulletins, attending one local code meeting per year, and building job packets that make your decisions transparent.

When security becomes part of the way you layout, wire, label, and document every system, inspectors see consistency, homeowners see care, and your team sees fewer come-backs. That is the quiet definition of compliance: work that stands on its own, even when the rules change around it.